Get Ready to Enter the World of On-Demand Manufacturing: 3D Printing and Logistics Explained

Let’s Talk On-Demand Manufacturing

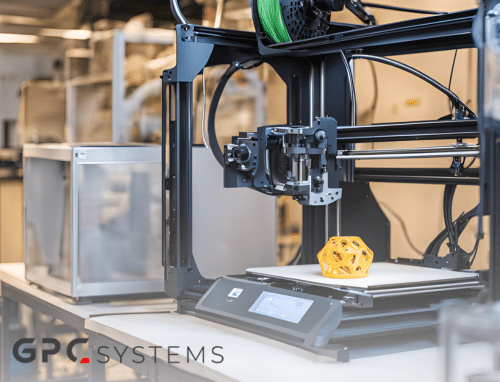

On-demand manufacturing, propelled by the advent of 3D printing, is transforming the industrial landscape. This technology is revolutionising traditional manufacturing processes, enabling companies to produce goods as needed rather than maintaining large inventories. With 3D printing taking centre stage, it is crucial to understand its profound impact on the manufacturing and logistics sectors.

What’s the Deal with 3D Printing?

3D printing, or additive manufacturing, involves creating objects layer by layer from digital models, using materials such as plastics, metals, and even food. This process can produce a wide range of items, from custom phone cases to complex prototypes, rapidly and efficiently. The technology is versatile and accessible, capable of operating in a garage or a state-of-the-art lab. According to a recent report, the global 3D printing market is expected to reach £34.8 billion by 2024, growing at a CAGR of 23.3% from 2021 to 2024, illustrating its expanding influence and potential.

How Logistics Play a Key Role in On-Demand Manufacturing

Logistics is pivotal in on-demand manufacturing. When a product is created using a 3D printer, the logistics network ensures its delivery to the customer. This involves managing the supply chain, warehousing, and transportation to ensure that items reach their destination efficiently and intact. The integration of 3D printing and logistics streamlines the entire process, reducing lead times and enhancing delivery accuracy. It is estimated that effective logistics can reduce delivery times by up to 50%, significantly benefiting the end consumer.

Jumping into the World of On-Demand Manufacturing

Embracing on-demand manufacturing means leveraging the synergy between 3D printing and logistics. This combination allows for the swift creation and delivery of customised products, catering to specific customer needs. From bespoke phone cases to intricate prototypes, the collaboration between these two fields facilitates a seamless transition from design to delivery. As businesses adopt this model, they can expect enhanced flexibility and responsiveness to market demands, positioning themselves competitively in the industry.

The Benefits of 3D Printing and Logistics

The collaboration between 3D printing and logistics offers numerous advantages. Firstly, it drastically reduces production and delivery times, enabling quicker turnaround for customer orders. Secondly, on-demand manufacturing minimises waste, as products are made to order, aligning with sustainability goals. According to industry data, on-demand manufacturing can reduce inventory costs by up to 30% and decrease material waste by approximately 40%. These efficiencies not only benefit businesses but also contribute to environmental sustainability.

Addressing the Limitations of 3D Printing

While 3D printing holds significant promise, it is not without its limitations. One primary concern is the speed of production; additive manufacturing can be slower compared to traditional methods, particularly for large-scale production. Additionally, the range of materials suitable for 3D printing, though expanding, is still limited compared to conventional manufacturing techniques. Quality control and consistency also present challenges, as the final product can sometimes lack the durability or precision of those made through traditional processes. Addressing these limitations is crucial for the broader adoption of 3D printing in industrial applications.

How 3D Printing Will Change Logistics

- Decentralised Production: 3D printing could decentralise manufacturing, allowing products to be produced closer to the point of consumption. This would reduce the need for extensive transportation networks and large centralised factories, potentially leading to a more efficient and flexible supply chain.

- Reduction in Inventory: With the ability to produce items on demand, businesses could significantly reduce the amount of inventory they need to hold. This would not only cut storage costs but also minimise the risk of overproduction and obsolescence.

- Customisation and Personalisation: 3D printing enables mass customisation, allowing businesses to produce tailored products for individual customers without significant cost increases. This could lead to a shift in consumer expectations and demand for personalised goods.

- Streamlined Supply Chains: By integrating 3D printing, supply chains can become more streamlined, with fewer stages between production and delivery. This simplification can result in faster turnaround times and reduced logistics costs.

- Sustainability Improvements: On-demand production and reduced transportation needs could lower the environmental impact of manufacturing. By producing only what is needed, waste is minimised, and the carbon footprint of transportation is reduced.

- New Business Models: The flexibility of 3D printing opens the door for innovative business models, such as localised manufacturing hubs and service-based manufacturing, where companies offer printing services rather than selling physical products. This could revolutionise traditional business strategies and market dynamics.

By considering these theories, businesses can better prepare for the transformative effects of 3D printing on logistics and overall operations.

Ready to Revolutionise Your Business? Let’s Do This!

Businesses can significantly benefit from integrating on-demand manufacturing into their operations. This approach eliminates the need for large inventories, reduces production costs, and allows for the creation of personalised products that meet individual customer preferences. By adopting 3D printing and optimising logistics, companies can streamline their production processes, enhance customer satisfaction, and gain a competitive edge in the market. The future of manufacturing is here, and it’s time to embrace the change and revolutionise your business.

At GPC we are always looking ahead, join us for weekly updates!